Built-Up (BUR)

Built-Up Roofing

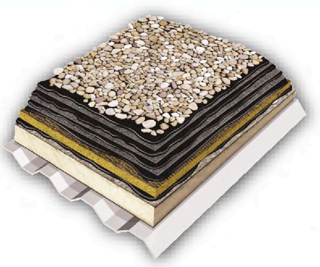

Built-up roofing is nothing new. The concept has been around for over 100 years, although the material and its installation have evolved during that time. Modern built-up products incorporate a rigid insulation layer for improved energy efficiency.

Most built-up roofing is comprised of three parts: bitumen material, ply sheets, and one or more surfacing materials. The bitumen can be either “hot,” meaning it is heated so that it liquefies during installation, or it can be “cold,” which is more like an adhesive and is not heated. Cold built-up roofing can be sprayed or applied with a squeegee. It does not give off toxic fumes during application and is not dependent on weather. It also offers better performance than hot built-up roofing.

Surfacing materials form the top layer and may consist of small stones or finer gravel, depending on the application. This layer provides a finished look and helps protect the layers below from sunlight and damage from flying or falling debris. It also makes the roof safe to walk on. One special type of built-up roofing, called ballasted roofing, uses large stones (about 1 1/2 to 2 1/2 inches in diameter) for the surface layer. With a ballasted system, the lower layers are not adhered or fastened to the roof structure, and the heavy surface layer keeps the roofing in place.

How Built-Up is Covered

- No Surfacing: Sometimes the felt is left exposed and no surfacing is applied. This is acceptable temporarily during construction, but a surfacing should always be applied. Leaving an exposed surface will begin to deteriorate the felts from the top. While there are multiple layers of felt, leaving it exposed will shorten the life of the roof.

- Emulsion or Aluminum Coating: Aluminum coating mixed with an emulsion was formerly popular because it allowed for a low cost surfacing with highly reflective properties. Over time, the aluminum would weather and disappear.

- Asphalt Floodcoat: Sometimes called a glaze, the felts are covered with a flood of asphalt. This results in ‘alligatoring,’ where the asphalt develops cracks and separates.

- Gravel: A popular surfacing for a built-up roof is gravel. The gravel is embedded in a thick floodcoat of asphalt. Not all of the gravel sinks into the asphalt, leaving a top layer of loose gravel. Once complete, the gravel protects the roof from sun, rain and physical damage.

- Hybrid: This method involves installing a modified bitumen or granulated sheet over the plies. While the built-up system is prized for its tensile strength, its ability to hold strong against building movement, the modified bitumen cap sheet allows flexibility. The hybrid system provides the best of both.